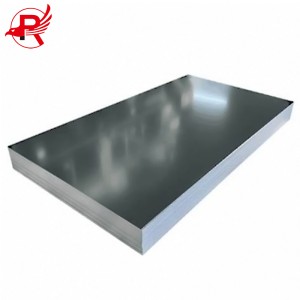

Qiimaha ugu Fiican Tayada Sare 0.27mm Kuleyl Lagu Shubay ASTM A653M-06a Xaashi Bir ah oo Galvanized ah

Waxaa jira faa'iidooyin badan oo isticmaalka xaashida birta galvanized ah:

1. Iska caabbinta daxalka: Xaashida birta galvanized waxaa lagu dahaadhay lakab zinc ah, taasoo ka dhigaysa mid aad u adkaysata daxalka.

2. Waarta:Saxan Bir ah oo La Galiyeywaa mid aad u waara oo u adkeysan kara xaaladaha cimilada ee daran, taasoo ka dhigaysa doorasho aad u fiican oo loogu talagalay isticmaalka dibadda.

3. Waxtarka kharash-oolnimada: Birta galvanized-ka ah waa mid dhaqaale ahaan la mid ah marka loo eego biraha kale, taasoo ka dhigaysa doorasho caan ah oo loogu talagalay codsiyada kala duwan.

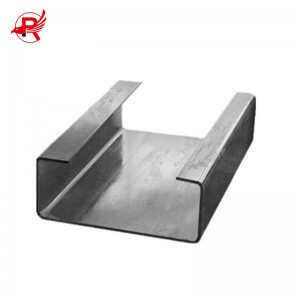

4. Si fudud loo shaqayn karo: Xaashi bir ah oo galvanized ah ayaa si fudud loogu shaqayn karaa waxaana si fudud loogu samayn karaa qaabab iyo cabbirro kala duwan.

5. Dayactir yar: Xaashida birta ah ee galvanized-ka ah waxay u baahan tahay dayactir yar, taasoo ka dhigaysa qalab aan dhib lahayn oo loogu talagalay codsiyada kala duwan.

6. Iska caabbinta dabka: Xaashida birta ah ee galvanized-ka ah lama guban karo, taasoo ka dhigaysa mid ku habboon in loo isticmaalo dhismaha iyo codsiyada warshadaha.

1. Iska caabbinta daxalka, rinjiyeynta, qaabaynta iyo alxanka booska.

2. Waxay leedahay isticmaalyo kala duwan, oo inta badan loo isticmaalo qaybo ka mid ah qalabka guryaha yaryar ee u baahan muuqaal wanaagsan, laakiin way ka qaalisan tahay SECC, sidaa darteed soosaarayaal badan ayaa u wareegaya SECC si ay u badbaadiyaan kharashyada.

3. Waxaa loo qaybiyaa zinc: cabbirka spangle-ka iyo dhumucda lakabka zinc-ku waxay tilmaami karaan tayada galvanizing-ka, marka uu yar yahay oo uu dhumucdiisuna ka sii wanaagsan tahay. Soo-saarayaashu waxay sidoo kale ku dari karaan daawaynta ka hortagga faraha. Intaa waxaa dheer, waxaa lagu kala saari karaa dahaadhkiisa, sida Z12, taasoo la macno ah in wadarta guud ee dahaarka labada dhinac ay tahay 120g/mm.

Xaashi Bir ah oo la galvanized, oo sidoo kale loo yaqaan xaashi bir ah oo galvanized ah ama xaashi zinc-dahaar leh, waa nooc ka mid ah xaashi bir ah oo lagu dahaadhay lakab zinc ah si looga hortago miridhku. Isticmaalka xaashida galvanized waa mid baahsan sababtoo ah cimri dhererkeeda iyo iska caabbinta miridhku. Maqaalkani wuxuu sahaminayaa adeegsigeeda kala duwan ee warshadaha kala duwan.

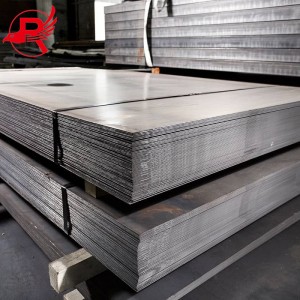

Warshadaha Dhismaha: Warshadaha dhismaha, go'yaasha galvanized-ka ah ayaa badanaa loo isticmaalaa saqafka iyo dahaarka. Sababtoo ah cimrigooda iyo awooddooda ay u leeyihiin inay u adkeystaan xaaladaha cimilada ee adag, waxay noqdeen doorasho caan ah oo loogu talagalay saqafka guryaha, ganacsiga, iyo warshadaha. Go'yaasha galvanized-ka ah ayaa sidoo kale si caadi ah loogu isticmaalaa dhismaha dhismayaasha birta ah, buundooyinka, iyo waddooyinka waaweyn sababtoo ah xooggooda iyo isku hallayntooda.

Warshadaha Gawaarida:Saxan Bir ah oo la galvanized ah oo kululsi weyn ayaa loogu isticmaalaa warshadaha baabuurta. Waxaa loo isticmaalaa soo saarista jirka baabuurta, chassis-ka, iyo qaybaha kale sababtoo ah iska caabbinta daxalka iyo awoodda ay u leeyihiin inay u adkaystaan heerkulka xad-dhaafka ah iyo qoyaanka sare. Go'yaasha galvanized-ka ah ayaa sidoo kale loo isticmaalaa sidii ka hortag miridhku ku jiro si loo dheereeyo cimriga qaybaha baabuurta.

Warshadaha Beeraha: Warshadaha beeruhu waxay u isticmaalaan xaashiyo galvanized ah codsiyo kala duwan sida sameynta aqallo, silos, guryo xayawaan, iyo deyr. Tani waxay sabab u tahay awooddooda ay u adkeysan karaan soo-gaadhista xaaladaha cimilada ee kala duwan iyo iska caabbinta miridhku, taasoo hubinaysa waarta dhismayaashan.

Warshadaha Korontada: Go'yaal galvanized ah ayaa si weyn loogu isticmaalaa warshadaha korontada si loo abuuro qaab-dhismeedyo iyo qaybo waara oo waara sida khaanadaha qalabka korontada, tuubooyinka birta ah, qalabka nalalka, iyo qalabka fiilooyinka.

Warshadaha Qalabka: Go'yaasha galvanized-ka ah ayaa sidoo kale si weyn loogu isticmaalaa soo saarista qalabka guryaha ee kala duwan sida qalabka qaboojiyaha, qaboojiyaha, iyo mashiinnada dharka lagu dhaqo. Qalabkani wuxuu u baahan yahay agab adag oo waara oo u adkeysan kara falgallada kiimikada ee ka dhasha soo-gaadhista walxaha kala duwan, taasoo ka dhigaysa go'yaasha galvanized doorasho ku habboon.

Codsiyada Warshadaha: Go'yaasha galvanized-ka ah waxaa loo isticmaalaa codsiyo kala duwan oo warshadeed sida haamaha kaydinta, dhuumaha, iyo qalabka wax lagu farsameeyo. Waxaa loo isticmaalaa codsiyadan sababtoo ah waxay u adkeysan karaan soo-gaadhista xaaladaha deegaanka ee adag iyo sidoo kale kiimikooyinka sunta ah ee ku lug yeelan kara hababka warshadaha.

| Heerka Farsamada | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Heerka Birta | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340, SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); ama Macaamiisha Shuruudaha |

| Dhumucda | Shuruudaha macaamiisha |

| Ballaca | sida waafaqsan shuruudaha macaamiisha |

| Nooca Dahaarka | Birta Galvanized-ka ah ee kulul ee la rusheeyey (HDGI) |

| Dahaarka Zinc | 30-275g/m2 |

| Daaweynta Dusha Sare | Passivation(C), Saliidayn(O), Shaabadaynta Xabagta (L), Fosfating(P), Aan la daweyn(U) |

| Qaab-dhismeedka Dusha Sare | Dahaarka caadiga ah ee spangle (NS), dahaarka spangle ee la yareeyay (MS), oo aan lahayn spangle (FS) |

| Tayada | Waxaa ansixiyay SGS, ISO |

| ID | 508mm/610mm |

| Miisaanka gariiradda | 3-20 metric ton halkii gariirad |

| Xirmo | Warqadda biyaha ka ilaalisa waa baakad gudaha ah, bir galvanized ah ama bir dahaadh leh waa baakad dibadda ah, saxan ilaalo dhinac ah, ka dibna lagu duubay toddobo suun bir ah. ama sida waafaqsan shuruudaha macaamiisha. |

| Suuqa dhoofinta | Yurub, Afrika, Aasiyada Dhexe, Koonfur-bari Aasiya, Bariga Dhexe, Koonfurta Ameerika, Waqooyiga Ameerika, iwm. |

| Shaxda Isbarbardhigga Dhumucda Cabbirka | ||||

| Cabbirka | Fudud | Aluminium | Galvanized | Daxal lahayn |

| Cabbirka 3aad | 6.08mm | 5.83mm | 6.35mm | |

| Cabbirka 4 | 5.7mm | 5.19mm | 5.95mm | |

| Cabbirka 5 | 5.32mm | 4.62mm | 5.55mm | |

| Cabbirka 6 | 4.94mm | 4.11mm | 5.16mm | |

| Cabbirka 7 | 4.56mm | 3.67mm | 4.76mm | |

| Cabbirka 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Cabbirka 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Cabbirka 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Cabbirka 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Cabbirka 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Cabbirka 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Cabbirka 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Cabbirka 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Cabbirka 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Cabbirka 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Cabbirka 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Cabbirka 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Cabbirka 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Cabbirka 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Cabbirka 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Cabbirka 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Cabbirka 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Cabbirka 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Cabbirka 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Cabbirka 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Cabbirka 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Cabbirka 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Cabbirka 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Cabbirka 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Cabbirka 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Cabbirka 33 | 0.22mm | 0.18mm | 0.24mm | |

| Cabbirka 34 | 0.20mm | 0.16mm | 0.22mm | |

S: Ma soo-saare ayaad tahay?

J: Haa, waxaan nahay warshad. Waxaan leenahay warshad noo gaar ah oo ku taal Magaalada Tianjin, Shiinaha. Intaa waxaa dheer, waxaan la shaqeynaa shirkado badan oo dowladeed, sida BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP, iwm.

S: Ma heli karaa amar tijaabo ah oo kaliya dhowr tan?

J: Dabcan. Waxaan kuu soo rari karnaa xamuulka iyadoo la adeegsanayo adeegga LCL. (Cuntada weelka oo yar)

S: Haddii muunad bilaash ah?

J: Muunad la'aan, laakiin iibsaduhu wuxuu bixiyaa kharashka rarista.

S: Ma tahay alaab-qeybiye dahab ah oo ma hubisaa ganacsiga?

A: Waxaan toddoba sano oo dahab ah bixinnaa oo aan aqbalnaa dammaanadda ganacsiga.