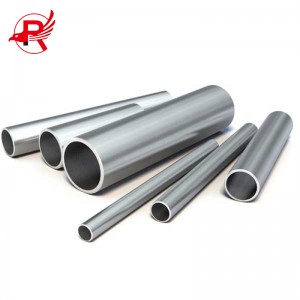

Tuubo/Tuubo Bir ah oo aan lahayn Birta Qurxinta ah oo Wareegsan oo SS ah oo SUS 304L 316 316L 304 ah

| Magaca Badeecada | Bir aan lahayn tuubo wareegsan |

| Heerka Caadiga ah | ASTM AISI DIN, EN, GB, JIS |

| Heerka Birta

| Taxanaha 200: 201,202 |

| Taxanaha 300: 301,304,304L,316,316L,316Ti,317L,321,309s,310s | |

| Taxanaha 400: 409L, 410, 410s, 420j1, 420j2, 430, 444, 441, 436 | |

| Bir laba-laab ah: 904L, 2205, 2507, 2101, 2520, 2304 | |

| Dhexroorka Dibadda | 6-2500mm (sida loogu baahdo) |

| Dhumucda | 0.3mm-150mm (sida loogu baahdo) |

| Dhererka | 2000mm/2500mm/3000mm/6000mm/12000mm (sida loogu baahdo) |

| Farsamada | aan kala go 'lahayn |

| Dusha sare | Lambarka 1aad 2B BA 6K Muraayad 8K Lambarka 4aad HL |

| Dulqaad | ±1% |

| Shuruudaha Qiimaha | FOB, CFR, CIF |

Tuubada birta aan lahayn waa nooc ka mid ah birta wareegsan ee godan, kaas oo inta badan loo isticmaalo dhuumaha gaadiidka warshadaha sida batroolka, warshadaha kiimikada, daaweynta caafimaadka, cuntada, warshadaha fudud, qalabka farsamada, iwm., iyo sidoo kale qaybaha qaab-dhismeedka farsamada. Intaa waxaa dheer, marka xoogga leexashada iyo leexashadu isku mid yihiin, miisaanku wuu fudud yahay, sidaas darteed waxaa sidoo kale si weyn loogu isticmaalaa soo saarista qaybaha farsamada iyo qaab-dhismeedka injineernimada. Sidoo kale waxaa badanaa loo isticmaalaa alaabta guriga iyo qalabka jikada, iwm.

Fiiro gaar ah:

1. Sampling bilaash ah, 100% hubinta tayada iibka kadib, Taageer hab kasta oo lacag bixin ah;

2. Dhammaan qeexitaannada kale ee tuubooyinka birta kaarboonka wareegsan ayaa laga heli karaa iyadoo loo eegayo baahidaada (OEM&ODM)! Qiimaha warshadda waxaad ka heli doontaa ROYAL GROUP.

Waxyaabaha Kiimikada ee Tuubada Birta ah ee aan lahayn

| Halabuurka Kiimikada % | ||||||||

| Fasal | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13 .0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0 · 28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0. 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

Iyada oo loo marayo habab kala duwan oo loo farsameeyo duubista qabow iyo dib-u-habaynta dusha sare ka dib marka la rogo, dhammaystirka dusha sare ee birta aan miridhku lahaynbaars waxay yeelan karaan noocyo kala duwan.

Tayada dusha sare ee birta aan miridhku lahayn waa muhiim maadaama ay si toos ah u saamayso iska caabbinta miridhku. Daxalka waa dhacdo dabiici ah oo dhacda marka biradu ay la falgasho deegaanka kiimikada ee ku xeeran, sida hawada ama qoyaanka.

Birta aan miridhku lahayn, chromium-ka ku jira dahaarka ayaa sameeya lakab ilaalin ah oo dusha sare ah kaas oo ka hortagaya in birtu ay la falgasho hareeraheeda. Lakabkaan waxaa loo yaqaan filim aan miridhku lahayn. Si kastaba ha ahaatee, filimka aan miridhku lahayn ee birta aan miridhku lahayn lama burburin karo. Haddii dusha sare uu waxyeelloobo ama wasakhoobo, filimku wuu dillaaci karaa, taasoo ka dhigaysa birta mid u nugul daxalka. Taasi waa sababta ilaalinta nadaafadda iyo hufnaanta dusha sare ee birta aan miridhku lahayn ay muhiim u tahay.

Waxaa jira dhowr siyaabood oo lagu hagaajin karo tayada dusha sare ee birta aan miridhku lahayn. Mid ka mid ah siyaabaha waa in la isticmaalo hab loo yaqaan passivation. Tani waxay ku lug leedahay daawaynta dusha sare xal gaar ah oo ka saaraya wax kasta oo wasakh ah isla markaana kor u qaada sifooyinka ilaalinta ee filimka aan firfircoonayn. Passivation waxaa lagu gaari karaa farsamooyin kala duwan sida qubeyska kiimikada ama electropolishing.

Si kale oo lagu ilaalin karo tayada dusha sare ee birta aan miridhku lahayn waa nadiifinta iyo dayactirka joogtada ah. Meelaha birta aan miridhku lahayn waa in lagu nadiifiyaa saabuun khafiif ah iyo maro jilicsan, wixii wasakh ah ama midab-beddel ah ee adagna waxaa laga saari karaa badeecooyin nadiifin oo gaar ah.

Guud ahaan, muhiimadda dhammaystirka birta aan miridhku lahayn lama buunbuunin karo. Tayada dusha sare waa muhiim si loo hubiyo cimriga iyo cimriga agabka. Iyadoo la raacayo habraacyada nadiifinta iyo dayactirka saxda ah, birta aan miridhku lahayn waxay sii wadi kartaa inay bixiso waxqabad wanaagsan iyo soo jiidasho bilicsan sannado badan oo soo socda.

Birta aan lahayn birta waxaa loo yaqaanaa cimri dhererkeeda, iska caabbinta daxalka iyo kala duwanaanshaheeda. Waxaa badanaa loo isticmaalaa codsiyo kala duwan oo ay ku jiraan soo saarista tuubooyinka.

Tuubada birta aan daxalka lahayn waxaa si weyn loogu isticmaalaa goobaha warshadaha iyo dhismaha dhismayaasha iyo dhismayaasha. Habka wax soo saarka ee tuubooyinka birta aan daxalka lahayn waa geedi socod adag oo ku lug leh tallaabooyin badan.

Walxaha Ceeriin

Tallaabada ugu horreysa ee lagu sameeyo tuubooyinka birta aan daxalka lahayn waa in la helo walxo ceeriin ah. Qaybta ugu weyn ee birta aan daxalka lahayn waa bir, laakiin waxaa lagu daraa walxo kale si loo siiyo sifooyin gaar ah. Agabkan waxaa ka mid ah nikkel, chromium iyo molybdenum. Alaabada ceeriin ah si taxaddar leh ayaa loo xushaa oo la isku daraa iyadoo loo eegayo heerka la rabo ee birta aan daxalka lahayn. Qaybahaan waxaa markaa lagu dhalaaliyaa foorno heerkul sare leh, halkaas oo ay ku shidaan si ay u sameeyaan bir. Marka birta la sameeyo, waxaa lagu shubaa qaab si loo bilaabo habka qaabeynta agabka. Caaryada, oo badanaa laga sameeyo ciid ama dhoobo, waxaa loogu talagalay inay sameeyaan tuubooyin godan dhammaadka hawsha. Ka dib marka birta la shubo lagu shubo qaab-dhismeedka, waxaa loo oggol yahay inay qaboojiso oo adkaato. Qaabka ugu dambeeya waa tuubo leh geeso qallafsan iyo dusha sare oo aan sinnayn.

rogrog

Tallaabada xigta ee habka waa rogrogidda. Tuubada waxaa lagu shubaa taxane duubab ah oo cadaadiya oo qaabeeya walxaha, taasoo keenta dusha sare oo siman iyo dhexroor isku mid ah. Tuubada ayaa markaa la mariyaa mandrel-ka si loo hubiyo inuu si fiican u wareegsan yahay oo dhumucdiisuna ay isku mid tahay. Hawshan, oo loo yaqaan cabbiraadda, ayaa muhiim u ah hubinta in badeecada la dhammeeyay ay buuxiso shuruudaha loo baahan yahay.

Jarida iyo Dhammaystirka

Marka tuubada la cabbiro, waa waqtigii la jari lahaa oo la dhammayn lahaa. Tan waxaa ka mid ah jarista tuubada dhererka la rabo iyo simida geesaha qallafsan ama burrs. Kadib tuubada ayaa la sifeeyaa si ay u hesho dhammaystir siman oo dhalaalaya. Habkani wuxuu gacan ka geystaa kordhinta iska caabbinta daxalka tuubada wuxuuna siiyaa muuqaal soo jiidasho leh.

Tijaabinta iyo Kormeerka

Badeecadaha la dhammeeyay waa inay maraan baaritaan iyo kormeer adag ka hor inta aan la iibin. Hubi tuubada haddii ay jiraan cillado sida dildilaacyo ama meelo miridhku ka baxo. Waxay sidoo kale ka gudubtay tijaabooyinka xoogga, cimri dhererka iyo iska caabbinta daxalka. Marka tuubooyinku ay dhaafaan dhammaan tijaabooyinka iyo kormeerka loo baahan yahay, waxay diyaar u tahay isticmaalka. Tuubada birta ah ee aan miridhku lahayn ee lagu sameeyo habkan waxaa loo isticmaalaa warshado kala duwan, oo ay ku jiraan dhismaha, saliidda iyo gaaska, iyo wax soo saarka.

Marka la soo koobo, soo saarista tuubooyinka birta aan miridhku lahayn waa geedi socod adag oo dhowr tallaabo ah oo ku lug leh marxalado badan laga bilaabo alaabta ceeriin ilaa alaabada la dhammeeyay. Waxay u baahan tahay fiiro gaar ah oo faahfaahsan, saxnaan iyo xakamaynta tayada si loo hubiyo in badeecada la dhammeeyay ay buuxiso shuruudaha loo baahan yahay oo ay ku habboon tahay codsiyo kala duwan.

Baakaduhu guud ahaan waa qaawan yihiin, silig bir ah ayay u xidhmaan, aad bayna u xoog badan yihiin.

Haddii aad leedahay shuruudo gaar ah, waxaad isticmaali kartaa baakadaha aan miridhku karin, oo ka sii qurux badan.

Gaadiidka:Degdeg ah (Gaarsiinta Muunadda), Hawada, Tareenka, Dhulka, Maraakiibta Badda (FCL ama LCL ama Bulk)

Macaamiisheena

S: Ma soo-saare ayaad tahay?

A: Haa, waxaan nahay soo saaraha tuubooyinka birta ah ee wareega oo ku yaal magaalada Tianjin, Shiinaha

S: Ma heli karaa amar tijaabo ah oo kaliya dhowr tan?

J: Dabcan. Waxaan kuu soo rari karnaa xamuulka iyadoo la adeegsanayo adeegga LCL. (Cuntada weelka oo yar)

S: Haddii muunad bilaash ah?

J: Muunad la'aan, laakiin iibsaduhu wuxuu bixiyaa kharashka rarista.

S: Ma tahay alaab-qeybiye dahab ah oo ma hubisaa ganacsiga?

A: Waxaan toddoba sano oo dahab ah bixinnaa oo aan aqbalnaa dammaanadda ganacsiga.