Tayada Sare ee Z275 DX51D Gi Warqad Qabow oo Galvanized ah oo la duubay

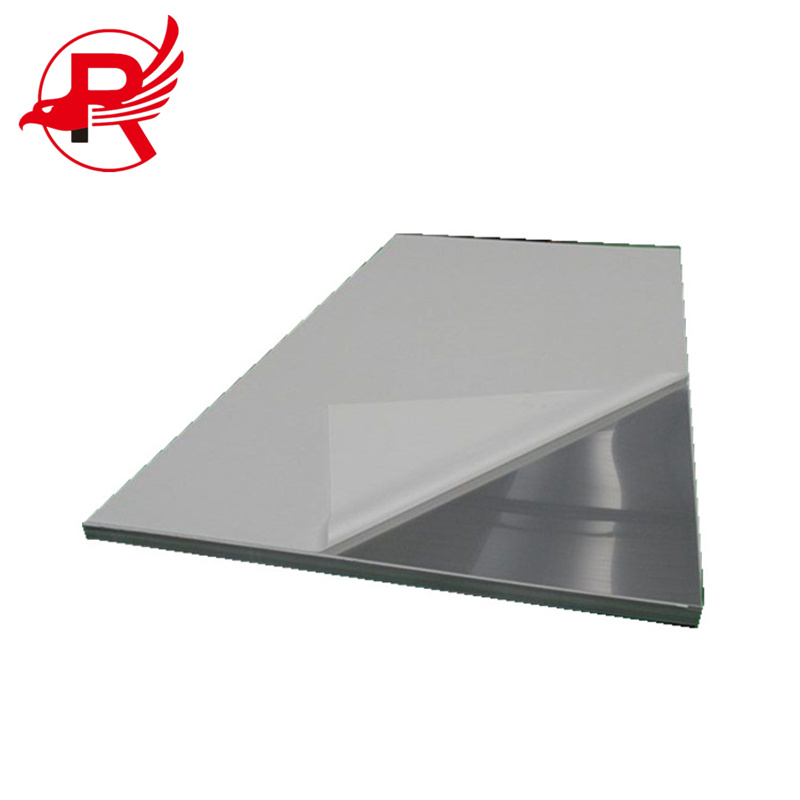

Xaashi la galvanizedWaxaa loola jeedaa xaashi bir ah oo lagu dahaadhay lakab zinc ah oo dusha sare ah. Galvanization waa hab dhaqaale ahaan waxtar leh oo looga hortago miridhku oo inta badan la isticmaalo, qiyaastii kala bar wax soo saarka zinc-ka adduunkana waxaa loo isticmaalaa habkan.

Sida ku cad hababka wax soo saarka iyo farsamaynta, waxaa loo qaybin karaa qaybaha soo socda:

Xaashi Bir ah oo la galvanized. Saxanka birta khafiifka ah ku dhex rid haanta zinc-ka ee dhalaalaysa si aad u samayso saxanka birta khafiifka ah oo leh lakab zinc ah oo dusha sare ku dheggan. Waqtigan xaadirka ah, habka galvanization-ka ee joogtada ah waxaa inta badan loo isticmaalaa wax soo saarka, taas oo ah, saxanka birta ee duuban ayaa si joogto ah loogu dhex shubaa haan galvanizing ah oo leh zinc dhalaalay si loo sameeyo saxan bir galvanized ah;

Saxan bir ah oo galvanized ah oo la isku daray. Noocan birta ah waxaa sidoo kale lagu sameeyaa habka kulul-mariska, laakiin waxaa lagu kululeeyaa ilaa 500℃ isla markiiba ka dib marka laga soo baxo haanta, si ay u samayso filim bir ah oo zinc iyo bir ah. Xaashidan galvanized waxay leedahay dhegdheg rinji oo wanaagsan iyo alxan;

Saxan bir ah oo koronto ku shaqeeya. Guddi bir ah oo galvanized ah oo lagu sameeyay electroplating ayaa leh habayn wanaagsan. Si kastaba ha ahaatee, dahaadhku waa khafiif yahay iska caabbintiisuna ma fiicna sida xaashida galvanized ee kulul lagu shubo.

1. Iska caabbinta daxalka, rinjiyeynta, qaabaynta iyo alxanka booska.

2. Waxay leedahay isticmaalyo kala duwan, oo inta badan loo isticmaalo qaybo ka mid ah qalabka guryaha yaryar ee u baahan muuqaal wanaagsan, laakiin way ka qaalisan tahay SECC, sidaa darteed soosaarayaal badan ayaa u wareegaya SECC si ay u badbaadiyaan kharashyada.

3. Waxaa loo qaybiyaa zinc: cabbirka spangle-ka iyo dhumucda lakabka zinc-ku waxay tilmaami karaan tayada galvanizing-ka, marka uu yar yahay oo uu dhumucdiisuna ka sii wanaagsan tahay. Soo-saarayaashu waxay sidoo kale ku dari karaan daawaynta ka hortagga faraha. Intaa waxaa dheer, waxaa lagu kala saari karaa dahaadhkiisa, sida Z12, taasoo la macno ah in wadarta guud ee dahaarka labada dhinac ay tahay 120g/mm.

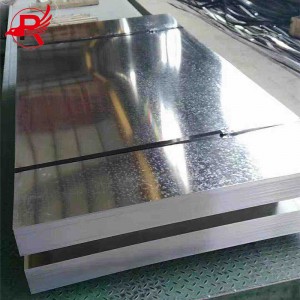

Saxan Bir ah oo la galvanized ah oo kululiyo alaabada birta xariijimaha ah waxaa inta badan loo isticmaalaa dhismaha, warshadaha fudud, baabuurta, beeraha, xannaanada xoolaha, kalluumeysiga iyo warshadaha ganacsiga. Kuwaas waxaa ka mid ah warshadaha dhismaha waxaa inta badan loo isticmaalaa in lagu soo saaro guddiyada saqafka warshadaha iyo dhismayaasha rayidka ah ee ka hortagga daxalka, shabakadaha saqafka, iwm.; warshadaha warshadaha iftiinka waxay u isticmaalaan inay soo saaraan qolofka qalabka guryaha, qiiqa dabka, qalabka jikada, iwm., warshadaha baabuurtana waxaa inta badan loo isticmaalaa in lagu soo saaro qaybo u adkaysta daxalka baabuurta, iwm.; Beeraha, xannaanada xoolaha iyo kalluumeysiga waxaa inta badan loo isticmaalaa kaydinta iyo rarista hadhuudhka, hilibka la qaboojiyey iyo alaabta biyaha, iwm.; ganacsiga waxaa inta badan loo isticmaalaa kaydinta iyo rarista agabka, qalabka baakadaha, iwm.

| Heerka Farsamada | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Heerka Birta | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340, SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); ama Macaamiisha Shuruudaha |

| Dhumucda | Shuruudaha macaamiisha |

| Ballaca | sida waafaqsan shuruudaha macaamiisha |

| Nooca Dahaarka | Birta Galvanized-ka ah ee kulul ee la rusheeyey (HDGI) |

| Dahaarka Zinc | 30-275g/m2 |

| Daaweynta Dusha Sare | Passivation(C), Saliidayn(O), Shaabadaynta Xabagta (L), Fosfating(P), Aan la daweyn(U) |

| Qaab-dhismeedka Dusha Sare | Dahaarka caadiga ah ee spangle (NS), dahaarka spangle ee la yareeyay (MS), oo aan lahayn spangle (FS) |

| Tayada | Waxaa ansixiyay SGS, ISO |

| ID | 508mm/610mm |

| Miisaanka gariiradda | 3-20 metric ton halkii gariirad |

| Xirmo | Warqadda biyaha ka ilaalisa waa baakad gudaha ah, bir galvanized ah ama bir dahaadh leh waa baakad dibadda ah, saxan ilaalo dhinac ah, ka dibna lagu duubay toddobo suun bir ah. ama sida waafaqsan shuruudaha macaamiisha. |

| Suuqa dhoofinta | Yurub, Afrika, Aasiyada Dhexe, Koonfur-bari Aasiya, Bariga Dhexe, Koonfurta Ameerika, Waqooyiga Ameerika, iwm. |

| Shaxda Isbarbardhigga Dhumucda Cabbirka | ||||

| Cabbirka | Fudud | Aluminium | Galvanized | Daxal lahayn |

| Cabbirka 3aad | 6.08mm | 5.83mm | 6.35mm | |

| Cabbirka 4 | 5.7mm | 5.19mm | 5.95mm | |

| Cabbirka 5 | 5.32mm | 4.62mm | 5.55mm | |

| Cabbirka 6 | 4.94mm | 4.11mm | 5.16mm | |

| Cabbirka 7 | 4.56mm | 3.67mm | 4.76mm | |

| Cabbirka 8 | 4.18mm | 3.26mm | 4.27mm | 4.19mm |

| Cabbirka 9 | 3.8mm | 2.91mm | 3.89mm | 3.97mm |

| Cabbirka 10 | 3.42mm | 2.59mm | 3.51mm | 3.57mm |

| Cabbirka 11 | 3.04mm | 2.3mm | 3.13mm | 3.18mm |

| Cabbirka 12 | 2.66mm | 2.05mm | 2.75mm | 2.78mm |

| Cabbirka 13 | 2.28mm | 1.83mm | 2.37mm | 2.38mm |

| Cabbirka 14 | 1.9mm | 1.63mm | 1.99mm | 1.98mm |

| Cabbirka 15 | 1.71mm | 1.45mm | 1.8mm | 1.78mm |

| Cabbirka 16 | 1.52mm | 1.29mm | 1.61mm | 1.59mm |

| Cabbirka 17 | 1.36mm | 1.15mm | 1.46mm | 1.43mm |

| Cabbirka 18 | 1.21mm | 1.02mm | 1.31mm | 1.27mm |

| Cabbirka 19 | 1.06mm | 0.91mm | 1.16mm | 1.11mm |

| Cabbirka 20 | 0.91mm | 0.81mm | 1.00mm | 0.95mm |

| Cabbirka 21 | 0.83mm | 0.72mm | 0.93mm | 0.87mm |

| Cabbirka 22 | 0.76mm | 0.64mm | 085mm | 0.79mm |

| Cabbirka 23 | 0.68mm | 0.57mm | 0.78mm | 1.48mm |

| Cabbirka 24 | 0.6mm | 0.51mm | 0.70mm | 0.64mm |

| Cabbirka 25 | 0.53mm | 0.45mm | 0.63mm | 0.56mm |

| Cabbirka 26 | 0.46mm | 0.4mm | 0.69mm | 0.47mm |

| Cabbirka 27 | 0.41mm | 0.36mm | 0.51mm | 0.44mm |

| Cabbirka 28 | 0.38mm | 0.32mm | 0.47mm | 0.40mm |

| Cabbirka 29 | 0.34mm | 0.29mm | 0.44mm | 0.36mm |

| Cabbirka 30 | 0.30mm | 0.25mm | 0.40mm | 0.32mm |

| Cabbirka 31 | 0.26mm | 0.23mm | 0.36mm | 0.28mm |

| Cabbirka 32 | 0.24mm | 0.20mm | 0.34mm | 0.26mm |

| Cabbirka 33 | 0.22mm | 0.18mm | 0.24mm | |

| Cabbirka 34 | 0.20mm | 0.16mm | 0.22mm | |

1. Waa maxay qiimahaagu?

Qiimayaashayadu way isbeddeli karaan iyadoo ku xiran saadka iyo arrimaha kale ee suuqa. Waxaan kuu soo diri doonnaa liis qiimo oo la cusbooneysiiyay ka dib marka shirkaddaadu la xiriirto

naga hel macluumaad dheeraad ah.

2. Ma haysataa tiro dalab oo ugu yar?

Haa, waxaan u baahanahay dhammaan dalabaadka caalamiga ah inay lahaadaan tiro dalab oo ugu yar oo socda. Haddii aad rabto inaad dib u iibiso laakiin aad u yar, waxaan kugula talineynaa inaad booqato boggayaga internetka

3. Ma keeni kartaa dukumentiyada khuseeya?

Haa, waxaan bixin karnaa inta badan dukumentiyada oo ay ku jiraan Shahaadooyinka Falanqaynta / U hoggaansanaanta; Caymiska; Asalka, iyo dukumentiyada kale ee dhoofinta marka loo baahdo.

4. Waa maxay celceliska waqtiga hogaaminta?

Shaybaarada, waqtiga hogaamintu waa qiyaastii 7 maalmood. Wax soo saarka ballaaran, waqtiga hogaamintu waa 5-20 maalmood ka dib marka la helo lacagta dhigaalka. Waqtiyada hogaamintu waxay dhaqan galaan marka

(1) waxaan helnay deebaajigaaga, iyo (2) waxaan haysannaa oggolaanshahaaga kama dambaysta ah ee alaabtaada. Haddii waqtiyada aanu bixinno aysan la shaqeyn waqtiga kama dambaysta ah, fadlan dib u eeg shuruudahaaga iibkaaga. Dhammaan kiisaska waxaan isku dayi doonnaa inaan daboolno baahiyahaaga. Inta badan kiisaska waan awoodnaa inaan sidaas sameyno.

5. Noocyadee hababka lacag bixinta ayaad aqbashaa?

30% kahor T/T, 70% waxay noqon doontaa kahor dhoofinta aasaasiga ah ee FOB; 30% kahor T/T, 70% marka loo eego nuqulka BL basic ee CIF.