Qalabka Birta ASTM A36 iyo Tuubooyinka QalabkaSharaxaad

| Halbeegga | Faahfaahinta / Sharaxaadda |

| Magaca Badeecada | Tuubada Taageerada ASTM A36 ee ASTM / Tuubada Taageerada Birta Kaarboon |

| Heerka Agabka | Bir kaarboon qaab-dhismeed ah oo loo siman yahay ASTM A36 |

| Heerarka | waafaqsan ASTM A36 |

| Dhexroorka Dibadda | 48–60 mm (caadi ahaan) |

| Dhumucda Darbiga | 2.5–4.0 mm |

| Ikhtiyaarada Dhererka Tuubada | 6 m, 12 ft, ama dherer gaar ah oo loogu talagalay shuruudaha mashruuca |

| Nooca Tuubada | Dhisme aan kala go 'lahayn ama alxan leh |

| Ikhtiyaarada Dhammaystirka Dusha Sare | Madow (aan la daweyn), Kulul-Dip Galvanized (HDG), dahaarka epoxy/rinjiga ikhtiyaari ah |

| Xoogga Wax Soo Saarka | ≥ 250 MPa |

| Xoogga Tijaabada | 400–550 MPa |

| Faa'iidooyinka Muhiimka ah | Awood culays sare leh, iska caabbinta daxalka oo la hagaajiyay (Galvanized), cabbirro isku mid ah, rakibid iyo ka saarid badbaado leh & fudud |

| Isticmaalka Caadiga ah | Nidaamyada isku-dhafka, goobaha warshadaha, taageerooyinka dhismaha ee ku meel gaarka ah, diyaarinta |

| Shahaadada Tayada | U hoggaansanaanta heerka ISO 9001 iyo ASTM |

| Shuruudaha Lacag-bixinta | T/T 30% dhigaalka + 70% dheelitirka ka hor rarista |

| Waqtiga Bixinta Bixinta | Qiyaastii. 7-15 maalmood iyadoo ku xiran tirada |

Qalabka Birta ASTM A36 iyo Tuubooyinka Qalabka Cabbirka

| Dhexroorka Dibadda (mm / inji) | Dhumucda Darbiga (mm / inji) | Dhererka (m / ft) | Miisaanka Mitirkiiba (kg/m) | Awoodda Rarka Qiyaastii (kg) | Qoraallo |

| 48 mm / 1.89 inji | 2.5 mm / 0.098 inji | 6 mitir / 20 cagood | 4.5 kg/m | 500–600 | Bir madow, HDG ikhtiyaari ah |

| 48 mm / 1.89 inji | 3.0 mm / 0.118 inji | 12 mitir / 40 cagood | 5.4 kg/m | 600–700 | Si aan kala go 'lahayn ama loo alxamayn |

| 50 mm / 1.97 inji | 2.5 mm / 0.098 inji | 6 mitir / 20 cagood | 4.7 kg/m | 550–650 | Dahaarka HDG ikhtiyaari ah |

| 50 mm / 1.97 inji | 3.5 mm / 0.138 inji | 12 mitir / 40 cagood | 6.5 kg/m | 700–800 | Si aan kala go 'lahayn ayaa lagula talinayaa |

| 60 mm / 2.36 inji | 3.0 mm / 0.118 inji | 6 mitir / 20 cagood | 6.0 kg/m | 700–800 | Dahaarka HDG ayaa la heli karaa |

| 60 mm / 2.36 inji | 4.0 mm / 0.157 inji | 12 mitir / 40 cagood | 8.0 kg/m | 900–1000 | Saqafyo culus |

Qalabka Birta ASTM A36 iyo Tuubooyinka Qalabka Cabbirka

Faa'iidooyinka Qalabka Birta ee Ringlock

| Qaybta Habaynta | Ikhtiyaarada la heli karo | Sharaxaad / Kala Duwan |

| Cabbirrada | Dhexroorka Dibadda, Dhumucda Darbiga, Dhererka | Dhexroorka: 48–60 mm; Dhumucda Darbiga: 2.5–4.5 mm; Dhererka: 6–12 m (la hagaajin karo mashruuc kasta) |

| Habaynta | Jarjarid, Xidhmo, Qalab la diyaariyey, Laablaabid | Tuubooyinka waxaa loo jari karaa dherer ahaan, la duubi karaa, la qaloocin karaa, ama lagu rakibi karaa isku xirayaasha iyo agabka iyadoo loo eegayo shuruudaha mashruuca. |

| Daaweynta Dusha Sare | Bir Madow, Kuleyl-Dhig ah oo Galvanized ah, Dahaarka Epoxy, Rinjiyeyn | Daaweynta dusha sare waxaa lagu xushay iyadoo lagu saleynayo baahiyaha ilaalinta daxalka gudaha/dibadda iyo ilaalinta daxalka |

| Calaamadaynta iyo Baakaynta | Calaamadaha Gaarka ah, Macluumaadka Mashruuca, Habka Rarista | Calaamadaha waxay muujinayaan cabbirka tuubada, heerka ASTM, lambarka dufcadda, macluumaadka warbixinta tijaabada; baakad ku habboon sariirta fidsan, weelka, ama keenista maxalliga ah |

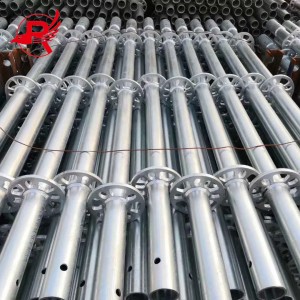

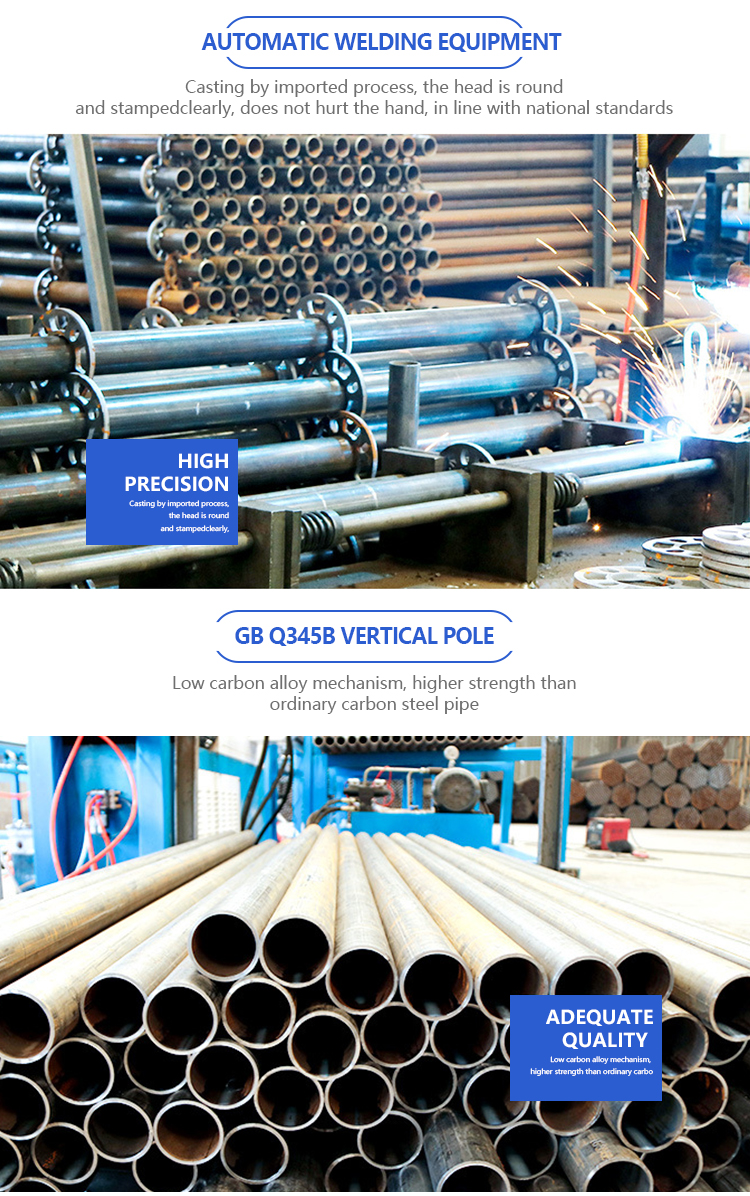

1. Tiknoolajiyadda horumarsan

Habka isku xirka nooca diskka waa qaabka isku xirka 0 ee caadiga ah. Naqshadeynta qanjidhada macquulka ah waxay gaari kartaa xoogga gudbinta ee ul kasta iyada oo loo marayo bartamaha qanjidhada, oo inta badan loo isticmaalo Yurub iyo Ameerika 0 iyo gobollada. Waa badeecad la casriyeeyay oo ka timid qalfoofka, tignoolajiyada qaan-gaarka ah iyo isku xirka. Qaab-dhismeed adag, deggan, ammaan ah oo la isku halleyn karo.

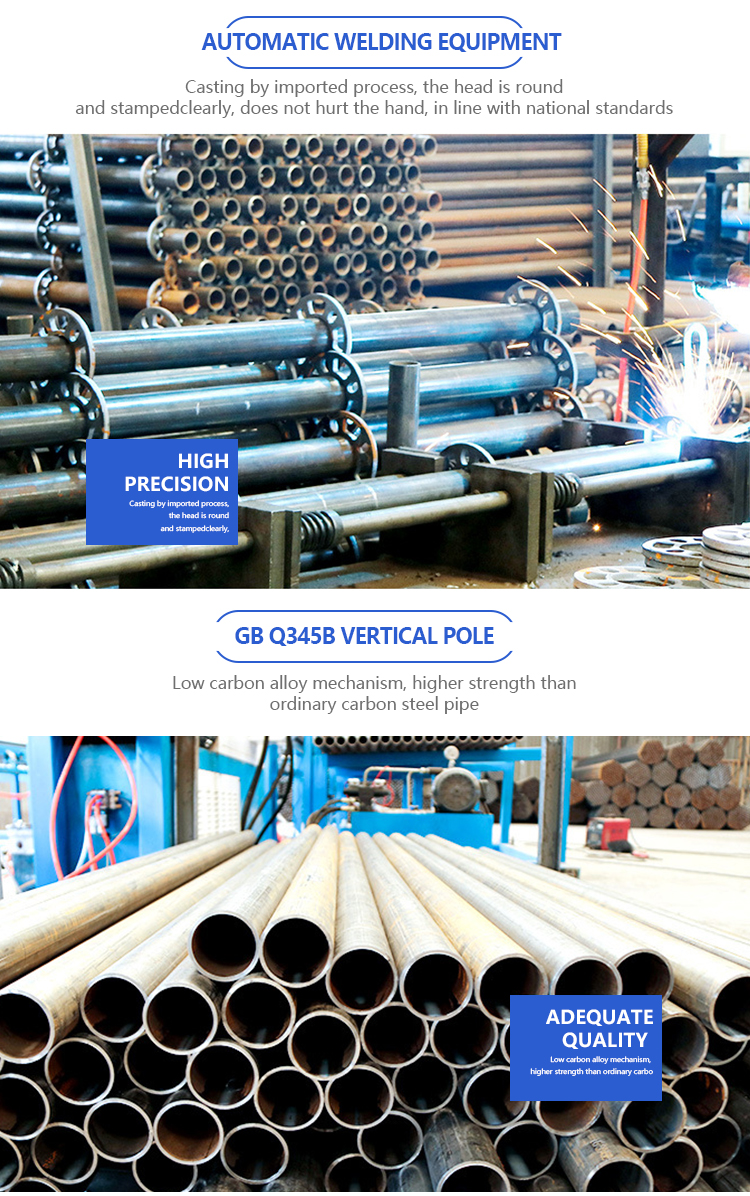

2. Cusbooneysiinta walxaha ceeriin ah

Alaabada ugu muhiimsan waa bir qaab-dhismeed oo aan daawad lahayn (heerka qaranka ee Q345B), xooggeedu waa 1.5-2 jeer ka sarreeya kan tuubooyinka birta kaarboon ee duugga ah ee dhaqameed (heerka qaranka ee Q235).

3. Habka galvanization-ka kulul

Qaybaha ugu muhiimsan waxay ka samaysan yihiin tignoolajiyada ka hortagga daxalka ee gudaha iyo dibaddaba, taas oo aan kaliya hagaajinayn cimriga adeegga badeecada, laakiin sidoo kale waxay bixisaa dammaanad dheeraad ah oo ku saabsan badbaadada, isla markaana ka dhigaysa mid qurux badan oo qurux badan.

4, tayo la isku halleyn karo

Badeecadu waxay ka bilaabataa jarista, habka wax soo saarka oo dhan waa inuu maraa 20 ilaa habka, tallaabo kastana waxaa lagu fuliyaa si gaar ah si loo yareeyo faragelinta arrimaha aadanaha, gaar ahaan soo saarista isgoysyada iyo tiirarka, iyadoo la adeegsanayo mashiinka alxanka oo si buuxda otomaatig ah u horumarsan. Badeecadu waxay leedahay saxnaan sare, is-weydaarsi xooggan iyo tayo deggan oo la isku halleyn karo.

5, awood qaadis oo weyn

Marka la soo qaado qaab-dhismeedka taageerada culus ee 60 taxane ah, awoodda qaadidda ee la oggol yahay ee tiir keliya oo dhererkiisu yahay 5 mitir waa 9.5 tan (qodobka badbaadada 2). Culayska waxyeelladu wuxuu gaaray 19 tan. Waa 2-3 jeer ka badan badeecadaha dhaqameed.

6, qiyaas yar iyo miisaan fudud

Xaaladaha caadiga ah, masaafada u dhaxaysa tiirarka waa 1.5 mitir, 1.8 mitir, tallaabada isgoyska waa 1.5 mitir, farqiga weyn wuxuu gaari karaa 3 mitir, masaafada tallaabaduna waa 2 mitir. Sidaa darteed, xaddiga mugga taageerada isku midka ah ayaa la dhimi doonaa 1/2 marka la barbar dhigo badeecada caadiga ah, miisaankana waxaa la dhimi doonaa 1/2 ilaa 1/3.

7, si dhakhso ah isugu imaatinka, si fudud loo isticmaali karo, lacag kaydsan karo

Maadaama ay yar tahay miisaanka iyo miisaanka fudud awgeed, hawlwadeenku si fudud ayuu isugu soo ururin karaa. Kharashka kala-goynta, gaadiidka, kirada iyo dayactirka ayaa si waafaqsan loo badbaadin doonaa, xaaladaha caadiga ah.

Faahfaahinta Qalabka Kabaha Birta ee Ringlock

Habka Rakibaadda Qalabka Qalinjabinta Birta ah ee Ringlock

Warshadeenna