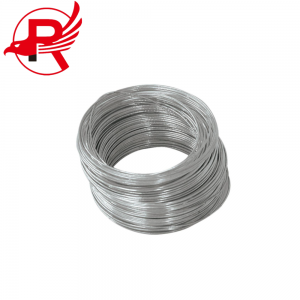

Qiimo Jaban Tayada Sare ee BWG 20 21 22 SAE1008 GI Xarigga Xidhitaanka ee Galvanized

| Magaca Badeecada | |

| 5kgs/duub, filim pp gudaha ah iyo maro Hassian ah oo dibadda ah ama bac pp tolmo leh oo dibadda ah | |

| 25kgs/duub, gudaha filimka pp iyo maro Hassian ah oo dibadda ah ama bacda la tolay ee dibadda ah | |

| 50kgs/duub, filim pp gudaha ah iyo maro Hassian ah oo dibadda ah ama bacda la tolay ee dibadda ah | |

| Alaab | Q195/Q235 |

| TIRADA SOO SAARKA | 1000tons/Bishii |

| MOQ | 5 tan |

| Codsiga | Silig isku xidha |

| Muddada lacag bixinta | T/T |

| Waqtiga keenista | qiyaastii 3-15 maalmood ka dib bixinta kahor |

| Cabbirka Silig | SWG(mm) | BWG(mm) | Mitir (mm) |

| 8 | 4.05 | 4.19 | 4 |

| 9 | 3.66 | 3.76 | 4 |

| 10 | 3.25 | 3.4 | 3.5 |

| 11 | 2.95 | 3.05 | 3 |

| 12 | 2.64 | 2.77 | 2.8 |

| 13 | 2.34 | 2.41 | 2.5 |

| 14 | 2.03 | 2.11 | 2.5 |

| 15 | 1.83 | 1.83 | 1.8 |

| 16 | 1.63 | 1.65 | 1.65 |

| 17 | 1.42 | 1.47 | 1.4 |

| 18 | 1.22 | 1.25 | 1.2 |

| 19 | 1.02 | 1.07 | 1 |

| 20 | 0.91 | 0.84 | 0.9 |

| 21 | 0.81 | 0.81 | 0.8 |

| 22 | 0.71 | 0.71 | 0.7 |

| Lambarka Siliga (Qiyaas) | AWG ama B&S (Inji) | Cabbirka AWG (MM) | Lambarka Siliga (Qiyaas) | AWG ama B&S (Inji) | Cabbirka AWG (MM) |

| 1 | 0.289297" | 7.348mm | 29 | 0.0113" | 0.287mm |

| 2 | 0.257627" | 6.543mm | 30 | 0.01" | 0.254mm |

| 3 | 0.229423" | 5.827mm | 31 | 0.0089" | 0.2261mm |

| 4 | 0.2043" | 5.189mm | 32 | 0.008" | 0.2032mm |

| 5 | 0.1819" | 4.621mm | 33 | 0.0071" | 0.1803mm |

| 6 | 0.162" | 4.115mm | 34 | 0.0063" | 0.1601mm |

| 7 | 0.1443" | 3.665mm | 35 | 0.0056" | 0.1422mm |

| 8 | 0.1285" | 3.264mm | 36 | 0.005" | 0.127mm |

| 9 | 0.1144" | 2.906mm | 37 | 0.0045" | 0.1143mm |

| 10 | 0.1019" | 2.588mm | 38 | 0.004" | 0.1016mm |

| 11 | 0.0907" | 2.304mm | 39 | 0.0035" | 0.0889mm |

| 12 | 0.0808" | 2.052mm | 40 | 0.0031" | 0.0787mm |

| 13 | 0.072" | 1.829mm | 41 | 0.0028" | 0.0711mm |

| 14 | 0.0641" | 1.628mm | 42 | 0.0025" | 0.0635mm |

| 15 | 0.0571" | 1.45mm | 43 | 0.0022" | 0.0559mm |

| 16 | 0.0508" | 1.291mm | 44 | 0.002" | 0.0508mm |

| 17 | 0.0453" | 1.15mm | 45 | 0.0018" | 0.0457mm |

| 18 | 0.0403" | 1.024mm | 46 | 0.0016" | 0.0406mm |

| 19 | 0.0359" | 0.9119mm | 47 | 0.0014" | 0.035mm |

| 20 | 0.032" | 0.8128mm | 48 | 0.0012" | 0.0305mm |

| 21 | 0.0285" | 0.7239mm | 49 | 0.0011" | 0.0279mm |

| 22 | 0.0253" | 0.6426mm | 50 | 0.001" | 0.0254mm |

| 23 | 0.0226" | 0.574mm | 51 | 0.00088" | 0.0224mm |

| 24 | 0.0201" | 0.5106mm | 52 | 0.00078" | 0.0198mm |

| 25 | 0.0179" | 0.4547mm | 53 | 0.0007" | 0.0178mm |

| 26 | 0.0159" | 0.4038mm | 54 | 0.00062" | 0.0158mm |

| 27 | 0.0142" | 0.3606mm | 55 | 0.00055" | 0.014mm |

| 28 | 0.0126" | 0.32mm | 56 | 0.00049" | 0.0124mm |

1)silig bir ah oo galvanized ah oo qabow la duubayWaxaa si weyn loogu isticmaalaa dhismaha, farsamada gacanta, diyaarinta shabagga siligga, soo saarista shabagga jillaab ee galvanized, shabagga daub, ilaalada waddooyinka, baakadaha alaabta iyo goobaha rayidka maalinlaha ah iyo kuwa kale.

Nidaamka isgaarsiinta,Usha Silig ee Birta Kaarboon ee Galvanizedwaxay ku habboon tahay khadadka gudbinta sida telegaraafka, taleefanka, baahinta fiilooyinka iyo gudbinta calaamadaha.

Nidaamka korontada, maadaama lakabka zinc ee siligga birta ahi uu yahay mid aad u weyn, dhumuc weyn leh isla markaana leh iska caabin wanaagsan oo daxalka ah, waxaa loo isticmaali karaa in lagu xiro fiilooyinka leh daxalka khadka ee daran.

2) KOOXDA BOQORADASilig Bir ah oo Galvanized ah, kaas oo leh tayo sare iyo awood sahay oo xooggan ayaa si ballaaran loogu isticmaalaa qaab-dhismeedka Birta iyo Dhismaha.

1. Muunad bilaash ah, 100% hubinta tayada iibka kadib, Taageer hab kasta oo lacag bixin ah;

2. Dhammaan qeexitaannada kale eePPGIayaa la heli karaa iyadoo loo eegayo baahiyahaaga

Shuruudaha (OEM&ODM)! Qiimaha warshadda waxaad ka heli doontaa ROYAL GROUP.

Soo saarista fiilada birta galvanized marka hore waxay qaadataa fiilada birta kaarboon ee ceeriin ah iyada oo loo marayo diirka, qajaarka, dhaqidda, saponification, qalajinta, sawiridda, annealing, qaboojinta, qajaarka, dhaqidda, khadka galvanized, baakadaha iyo habab kale.

Habka wax soo saarka ee fiilada birta galvanized waxay ku lug leedahay dhowr tallaabo si loo abuuro badeeco waarta oo u adkaysta daxalka. Waa kan dulmar guud oo ku saabsan habka wax soo saarka caadiga ah:

- Sawiridda Silig: Hawshu waxay ka bilaabataa in silig bir ah lagu sawiro taxane ah si loo yareeyo dhexroorkeeda ilaa cabbirka la rabo. Tallaabadani waxay sidoo kale gacan ka geysaneysaa hagaajinta xoogga jiidista iyo dhammaystirka dusha sare ee siliggu.

- Qaboojinta: Fiilada la jiiday waxaa markaa la mariyaa hab lagu damiyo, kaas oo ku lug leh kululaynta fiilada heerkul gaar ah ka dibna u oggolaanaya inay si tartiib ah u qaboojiso. Tani waxay yareysaa walbahaarka gudaha waxayna jilcisaa fiilada si loo sii farsameeyo.

- Qajaar la shiiday: Fiilada waxaa lagu miiraa xal aashito ah si looga saaro wixii wasakh ah, miridhku, ama wasakh kale oo dusha sare ah, taasoo hubinaysa in si fiican loogu dhejiyo dahaarka galvanized.

- GalvanizingFiilada la shiiday waxaa lagu dhex shubaa qubays zinc dhalaalay, ha ahaato mid kulul oo galvanizing ah ama mid elektaroonik ah. Marka la isku qaso qubays kulul, siligga waxaa si buuxda loogu dhex shubaa qubays zinc dhalaalay ah, halka marka la isku qaso electro-galvanizing ah, lakab khafiif ah oo zinc ah ayaa lagu dhejiyaa dusha sare ee siligga.

- Qaboojinta iyo DemintaKa dib marka la isku dhejiyo, fiilada waa la qaboojiyaa oo la damiyaa si loo adkeeyo dahaarka zinc-ka loona hagaajiyo dhegdheggiisa siligga birta ah.

- Daaweynta KadibIyada oo ku xidhan shuruudaha gaarka ah, fiilada birta galvanized-ka ah waxay mari kartaa habab dheeraad ah sida passivation, dahaarka chromate-ka, ama marin saliid si kor loogu qaado waxqabadkeeda iyo muuqaalkeeda.

- Baakaynta iyo Xidhmada: Siligga birta galvanized-ka ah ee la dhammeeyay ayaa markaa la isku shubaa oo la baakadeeyaa iyadoo loo eegayo tilmaamaha macaamiisha ee rarista iyo qaybinta.

Inta lagu jiro habka wax soo saarka, tallaabooyinka xakamaynta tayada ayaa la hirgeliyaa si loo hubiyo in siligga birta galvanized uu buuxiyo heerarka warshadaha ee xoogga jiidista, dhumucda dahaarka, iyo iska caabbinta daxalka. Intaa waxaa dheer, tixgelinta deegaanka iyo badbaadada ayaa muhiim u ah maaraynta iyo tuurista kiimikooyinka loo isticmaalo hababka qajaarka iyo galvanization.

Baakaduhu guud ahaan waa xirmo biyo celin karta, fiilooyin bir ah oo isku xiran, aad bay u xoog badan yihiin.

Gaadiidka: Degdeg ah (Gaarsiinta Muunadda), Hawada, Tareenka, Dhulka, Maraakiibta Badda (FCL ama LCL ama Bulk)

S: Ma soo-saare ayaad tahay?

J: Haa, waxaan nahay warshad soo saare. Waxaan leenahay warshad noo gaar ah oo ku taal Magaalada Tianjin, Shiinaha.

S: Ma heli karaa amar tijaabo ah oo kaliya dhowr tan?

J: Dabcan. Waxaan kuu soo rari karnaa xamuulka iyadoo la adeegsanayo adeegga LCL. (Cuntada weelka oo yar)

S: Haddii muunad bilaash ah?

J: Muunad la'aan, laakiin iibsaduhu wuxuu bixiyaa kharashka rarista.

S: Ma tahay alaab-qeybiye dahab ah oo ma hubisaa ganacsiga?

A: Waxaan toddoba sano oo dahab ah bixinnaa oo aan aqbalnaa dammaanadda ganacsiga.