API 5L Gr. B Kaarboon Xariiq aan kala go 'lahayn

| Darajooyinka | API 5L Fasalka B, X42, X52, X56, X60, X65, X70, X80 |

| Heerka Tilmaamaha | PSL1, PSL2 |

| Kala duwanaanshaha Dhexroorka Dibadda | 1/2” ilaa 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16 inji, 18 inji, 20 inji, 24 inji ilaa 40 inji. |

| Jadwalka dhumucda | SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, ilaa SCH 160 |

| Noocyada Wax-soo-saarka | Aan kala go 'lahayn (Kuleyl duuban iyo Qabow duuban), ERW (iska caabin koronto oo la alxamay), SAW (Qoryaha biyaha hoostooda lagu alxamay) ee LSAW, DSAW, SSAW, HSAW |

| Nooca Dhammaadka | Dhammaadyo godan, Dhammaadyo siman |

| Kala Duwanaanta Dhererka | SRL (Dhererka Hal-la'aanta ah), DRL (Dhererka Laba-labo ah ee aan kala sooca lahayn), 20 FT (6 mitir), 40 FT (12 mitir) ama, oo loo habeeyey |

| Koofiyadaha Ilaalinta | balaastig ama bir |

| Daaweynta Dusha Sare | Rinjiyeyn Dabiici ah, Labeen ah, Madow, FBE, 3PE (3LPE), 3PP, CWC (Miisaan Sibidh ah oo lagu dahaadhay) CRA oo lagu dahaadhay ama la safeeyey |

Tuubada API 5L waxaa loola jeedaa tuubo bir ah oo kaarboon ah oo loo isticmaalo nidaamyada gudbinta saliidda iyo gaaska. Waxaa sidoo kale loo isticmaalaa in lagu qaado dareerayaasha kale sida uumiga, biyaha, iyo dhoobada.

Qeexitaanka API 5L wuxuu daboolayaa noocyada wax soo saarka ee la alxamay iyo kuwa aan kala go 'lahayn.

Noocyada Alxanka: ERW, SAW, DSAW, LSAW, SSAW, Tuubada HSAW

Noocyada caadiga ah ee biibiile alxanka API 5L waa sida soo socota:

ERWAlxanka iska caabbinta korontada, oo caadi ahaan loo isticmaalo dhexroorka tuubooyinka oo ka yar 24 inji.

DSAW/SAWAlxanka qaansada ee laba-geesoodka ah/alxanka qaansada ee biyaha hoostooda ku jira, hab alxan oo kale oo loo isticmaalo tuubooyinka dhexroorka weyn.

LSAWAlxanka qulqulka dheer ee biyaha hoostooda ku jira, oo loo isticmaalo dhexroorka tuubooyinka ilaa 48 inji. Sidoo kale loo yaqaan habka wax soo saarka JCOE.

SSAW/HSAWAlxanka qaansada ee ku wareegsan/alxanka qaansada ee ku wareegsan, oo loo isticmaalo dhexroorka tuubooyinka ilaa 100 inji.

Noocyada Tuubooyinka aan tolnayn: Tuubo kulul oo aan tolnayn oo qabow la duubay

Tuubo bir ah oo aan kala go 'lahayn ayaa guud ahaan loo isticmaalaa tuubooyinka dhexroorkoodu yar yahay (badanaa ka yar 24 inji).

(Tuubo bir ah oo aan tolnayn ayaa laga doorbidaa tuubo la alxamay dhexroorkeedu ka yar yahay 150 mm (6 inji)).

Waxaan sidoo kale sameynaa tuubo dhexroor weyn oo aan lahayn silig. Adigoo adeegsanaya hab kulul oo la duubay, tuubo aan silig lahayn oo leh dhexroor ugu badan oo ah 20 inji (508 mm) ayaa la soo saari karaa. Haddii aad u baahan tahay inaad silig aan silig lahayn oo leh dhexroor ka badan 20", waxaan ku samayn karnaa tuubo aan silig lahayn habka kulul ee la ballaariyay oo leh dhexroor ilaa 40" (1016 mm).

API 5L waxaa ku jira darajooyin sida Darajada B, X42, X46, X52, X56, X60, X65, X70 iyo X80.

Tuubooyinka Birta API 5L waxaa laga heli karaa dhowr darajo oo bir ah oo ay ku jiraan Darajada B, X42, X46, X52, X56, X60, X65, X70 iyo X80. Heerka birta ayaa sii kordhaya, kantaroolka u dhigma kaarboonka ayaa sii adkaanaya, sifooyinka xoogga farsamada ayaa sii kordhaya.

Intaa waxaa dheer, qaab-dhismeedka kiimikada ee tuubooyinka API 5L ee alxanka leh iyo kuwa aan kala go 'lahayn oo leh heer bir ah oo isku mid ah ayaa leh farqi, kaas oo tuubooyinka alxanku ay leeyihiin baahiyo sare iyo kaarboon iyo sulfur yar.

Halabuurka Kiimikada ee tuubooyinka PSL 1 oo leh t ≤ 0.984” | |||||||

| Heerka Birta | Jajabka cufka, % oo ku salaysan falanqaynta kulaylka iyo badeecada a, g | ||||||

| C | Mn | P | S | V | Nb | Ti | |

| ugu badnaan b | ugu badnaan b | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | |

| Tuubo aan xuduud lahayn | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | - | - | - |

| B | 0.28 | 1.2 | 0.03 | 0.03 | c,d | c,d | d |

| X42 | 0.28 | 1.3 | 0.03 | 0.03 | d | d | d |

| X46 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X56 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X60 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X65 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| Tuubo la alxan | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | - | - | - |

| B | 0.26 | 1.2 | 0.03 | 0.03 | c,d | c,d | d |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | d | d | d |

| X46 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X56 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X60 | 0.26 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X65 | 0.26 e | 1.45 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.26e | 1.65 e | 0.03 | 0.03 | f | f | f |

| a. Cu ≤ = 0.50% Ni; ≤ 0.50%; Cr ≤ 0.50%; iyo Mo ≤ 0.15%, | |||||||

| b. Hoos u dhac kasta oo ah 0.01% oo ka hooseeya heerka ugu sarreeya ee kaarboonka ee la cayimay, koror 0.05% oo ka sarreeya heerka ugu sarreeya ee la cayimay ee Mn ayaa la oggol yahay, ilaa ugu badnaan 1.65% heerarka ≥ L245 ama B, laakiin ≤ L360 ama X52; ilaa ugu badnaan 1.75% heerarka > L360 ama X52, laakiin < L485 ama X70; iyo ilaa ugu badnaan 2.00% heerka L485 ama X70., | |||||||

| c. Haddii aan si kale loo raacin NB + V ≤ 0.06%, | |||||||

| d. Nb + V + TI ≤ 0.15%, | |||||||

| e. Haddii aan si kale lagu heshiin., | |||||||

| f. Haddii aan si kale loo raacin, FG + V = Ti ≤ 0.15%, | |||||||

| g. Lama oggola in si ula kac ah loogu daro B iyo haraaga B ≤ 0.001% | |||||||

| Halabuurka Kiimikada ee tuubada PSL 2 oo leh t ≤ 0.984” | |||||||||||||||||||||

| Heerka Birta | Jajabka cufka, % iyadoo lagu saleynayo falanqaynta kulaylka iyo badeecada | Kaarboon Equiv a | |||||||||||||||||||

| C | Si | Mn | P | S | V | Nb | Ti | Kale | CE IIW | CE PCm | |||||||||||

| ugu badnaan b | ugu badan | ugu badnaan b | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | ||||||||||||

| Tuubbo aan xuduud lahayn oo la welded | |||||||||||||||||||||

| BR | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42R | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| BN | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42N | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46N | 0.24 | 0.4 | 1.4 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X52N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X56N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.10f | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X60N | 0.24f | 0.45f | 1.40f | 0.025 | 0.015 | 0.10f | 0.05f | 0.04f | g,h,l | Sida lagu heshiiyay | |||||||||||

| BQ | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X52Q | 0.18 | 0.45 | 1.5 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X56Q | 0.18 | 0.45f | 1.5 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X60Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X65Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X70Q | 0.18f | 0.45f | 1.80f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X80Q | 0.18f | 0.45f | 1.90f | 0.025 | 0.015 | g | g | g | aniga,j | Sida lagu heshiiyay | |||||||||||

| X90Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | Sida lagu heshiiyay | |||||||||||

| X100Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | Sida lagu heshiiyay | |||||||||||

| Tuubo la alxan | |||||||||||||||||||||

| BM | 0.22 | 0.45 | 1.2 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X52M | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| X56M | 0.22 | 0.45f | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| X60M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X65M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X70M | 0.12f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X80M | 0.12f | 0.45f | 1.85f | 0.025 | 0.015 | g | g | g | aniga,j | .043f | 0.25 | ||||||||||

| X90M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | aniga,j | - | 0.25 | ||||||||||

| X100M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | aniga,j | - | 0.25 | ||||||||||

| a. SMLS t>0.787", xadka CE waa inuu ahaadaa sidii lagu heshiiyay. Xadka CEIIW ee la dabaqay fi C > 0.12% iyo xadka CEPcm ayaa lagu dabaqi karaa haddii C ≤ 0.12%, | |||||||||||||||||||||

| b. Dhimis kasta oo ah 0.01% oo ka hooseysa ugu badnaanta la cayimay ee C, koror 0.05% ah oo ka sarreeya ugu badnaanta la cayimay ee Mn ayaa la oggol yahay, ilaa ugu badnaan 1.65% darajooyin ≥ L245 ama B, laakiin ≤ L360 ama X52; ilaa ugu badnaan 1.75% darajooyin > L360 ama X52, laakiin < L485 ama X70; ilaa ugu badnaan 2.00% darajooyin ≥ L485 ama X70, laakiin ≤ L555 ama X80; iyo ilaa ugu badnaan 2.20% darajooyin > L555 ama X80., | |||||||||||||||||||||

| c. Haddii aan si kale loo raacin Nb = V ≤ 0.06%, | |||||||||||||||||||||

| d. Nb = V = Ti ≤ 0.15%, | |||||||||||||||||||||

| e. Haddii aan si kale lagu heshiin, Cu ≤ 0.50%; Ni ≤ 0.30% Cr ≤ 0.30% iyo Mo ≤ 0.15%, | |||||||||||||||||||||

| f. Haddii aan si kale lagu heshiin, | |||||||||||||||||||||

| g. Haddii aan si kale loo raacin, Nb + V + Ti ≤ 0.15%, | |||||||||||||||||||||

| h. Haddii aan si kale lagu heshiin, Cu ≤ 0.50% Ni ≤ 0.50% Cr ≤ 0.50% iyo MO ≤ 0.50%, | |||||||||||||||||||||

| i. Haddii aan si kale lagu heshiin, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.50% iyo MO ≤ 0.50%, | |||||||||||||||||||||

| j. B ≤ 0.004%, | |||||||||||||||||||||

| k. Haddii aan si kale lagu heshiin, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.55% iyo MO ≤ 0.80%, | |||||||||||||||||||||

| l. Dhammaan darajooyinka tuubbooyinka PSL 2 marka laga reebo darajooyinka leh qoraallada hoose ee j, kuwa soo socda ayaa khuseeya. Haddii aan si kale loo raacin, laguma oggola in si ula kac ah loogu daro B iyo haraaga B ≤ 0.001%. | |||||||||||||||||||||

| PSL | Xaaladda Bixinta | heerka tuubooyinka |

| PSL1 | Sida loo duubay, loo caadiyeeyay, loo caadiyeeyay oo la sameeyay | A |

| Sida loo duubay, caadi ka dhigaya duuban, la duubay heerkulbeeg, la sameeyay heerkulbeeg, caadi ka dhigaya sameysmo, caadi ka dhigaya, caadi ka dhigaya oo la hagaajin karo ama haddii la isku raaco Q&T SMLS oo keliya | B | |

| Sida loo duubay, caadi ka dhigaya duuban, la duubay heerkulbeeg, la sameeyay heerkulbeeg, caadi ka dhigaya sameysmo, caadi ka dhigaya, caadi ka dhigaya oo la hagaajin karo | X42, X46, X52, X56, X60, X65, X70 | |

| PSL 2 | Sida loo duubay | BR, X42R |

| Caadiyeynta duuban, caadiyeynta la sameeyay, caadi ah ama caadi ah oo la hagaajiyay | BN, X42N, X46N, X52N, X56N, X60N | |

| La damiyay oo la hagaajiyay | BQ, X42Q, X46Q, X56Q, X60Q, X65Q, X70Q, X80Q, X90Q, X100Q | |

| Heerkulbeegganikada la duubay ama heerkulbeegga la sameeyay | BM, X42M, X46M, X56M, X60M, X65M, X70M, X80M | |

| Heerkulbeegganikada la duubay | X90M, X100M, X120M | |

| Ku filan (R, N, Q ama M) ee darajooyinka PSL2, waxay ka tirsan tahay heerka birta |

PSL waa mid gaaban oo loo soo gaabiyo Heerka Sharaxaadda Badeecada waxayna ka kooban tahay PSL1 iyo PSL2. Waa wax u eg heerka tayada.

PSL1 iyo PSL2 kuma kala duwana oo keliya tijaabada, laakiin sidoo kale waxay ku kala duwan yihiin halabuurka kiimikada iyo sifooyinka farsamada.

PSL2 way ka adag tahay PSL1 marka loo eego halabuurka kiimikada, sifooyinka jilicsanaanta, tijaabada saameynta, tijaabada aan burburin, iwm.

Tijaabada Saamaynta

Tijaabada saameynta - Looma baahna PSL1, laakiin waa PSL2 (marka laga reebo X80).

Tijaabin aan burburin

PSL1 uma baahna tijaabo aan burburin laakiin PSL2 uma baahna.

(Tijaabinta aan burburin: Tijaabinta iyo tijaabinta aan burburin ee heerka API 5L waxay isticmaashaa raajada, ultrasonic, ama habab kale (iyada oo aan la burburin agabka) si loo ogaado cilladaha iyo cilladaha ku jira dhuumaha.)

Baakadu waaguud ahaan qaawan, xidhitaanka siligga birta ah, aad u badanxoog leh.

Haddii aad leedahay shuruudo gaar ah, waxaad isticmaali kartaaBaakadaha aan miridhku lahayn, oo ka sii qurux badan.

Taxaddarrada baakadaha iyo rarista tuubooyinka birta kaarboonka ah

1.API 5L tuubo bir ahwaa in laga ilaaliyaa waxyeelada ka dhalata isku dhaca, soo saarista iyo jarista inta lagu jiro rarista, kaydinta iyo isticmaalka.

2. Markaad isticmaaleyso tuubooyinka birta kaarboon, waa inaad raacdaa habraacyada badbaadada ee u dhigma oo aad fiiro gaar ah u yeelatid si aad uga hortagto qaraxyada, dabka, sunta iyo shilalka kale.

3. Inta la isticmaalayo,Tuubada API 5L ee birta kaarboonka ahwaa inay ka fogaadaan taabashada heerkulka sare, warbaahinta daxalka leh, iwm. Haddii loo isticmaalo deegaannadan, waa in la doortaa tuubooyinka birta kaarboonka ah ee laga sameeyay agab gaar ah sida iska caabbinta heerkulka sare iyo iska caabbinta daxalka.

4. Marka la dooranayo tuubooyinka birta kaarboon, tuubooyinka birta kaarboon ee agabka ku habboon iyo qeexitaannada waa in lagu xushaa iyadoo lagu saleynayo tixgelinno dhammaystiran sida deegaanka isticmaalka, sifooyinka dhexdhexaadka ah, cadaadiska, heerkulka iyo arrimo kale.

5. Kahor inta aan la isticmaalin tuubooyinka birta kaarboon, waa in la sameeyaa baaritaanno iyo baaritaanno lagama maarmaan ah si loo hubiyo in tayadooda ay buuxiso shuruudaha.

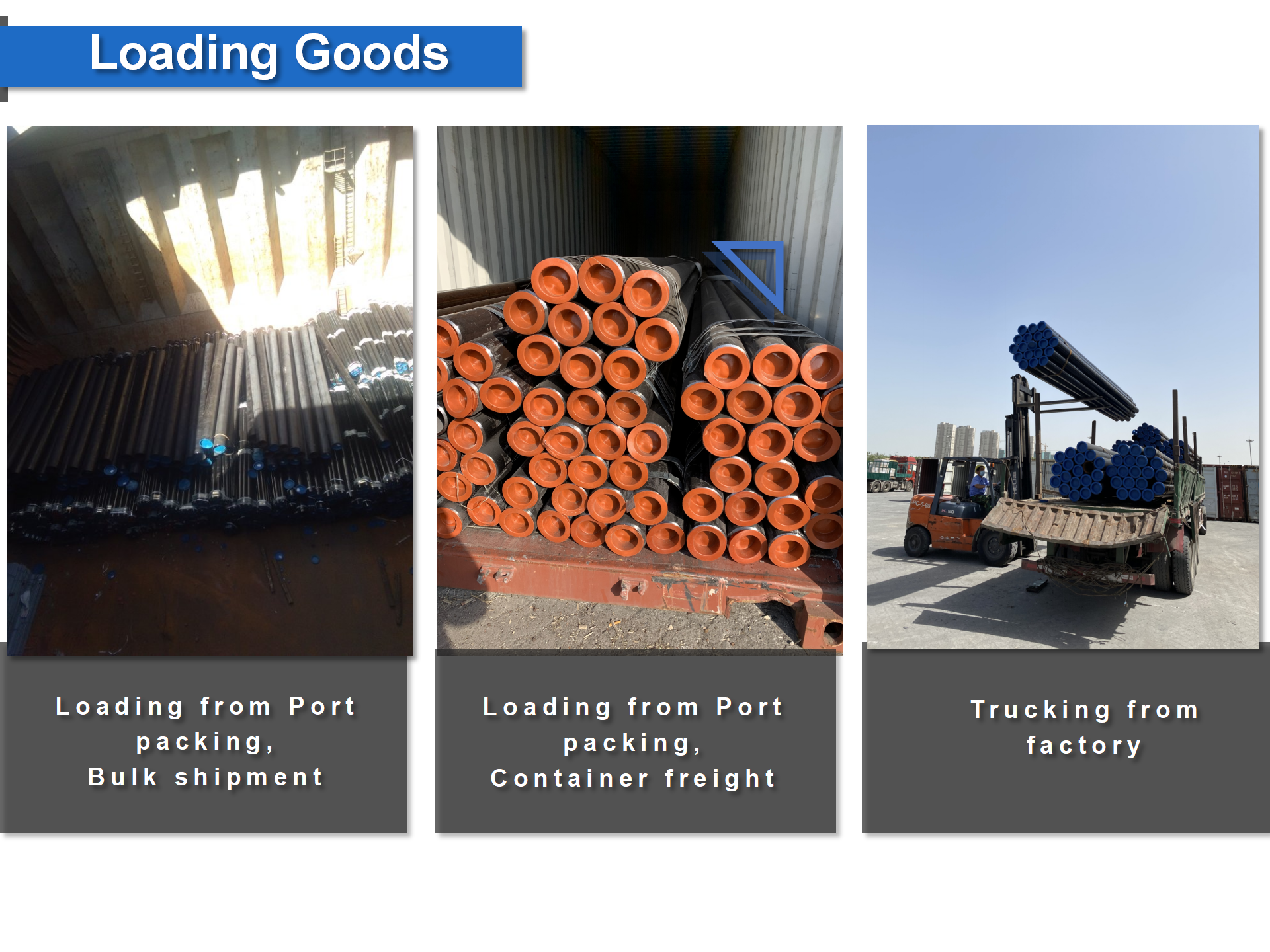

Gaadiidka:Duulimaad degdeg ah (Gaarsiinta Muunadda), Hawada, Tareenka, Dhulka, Maraakiibta Badda (FCL ama LCL ama Bulk)

S: Ma soo-saare ayaad tahay?

A: Haa, waxaan nahay soo-saare tuubo bir ah oo wareegsan oo ku yaal tuulada Daqiuzhuang, magaalada Tianjin, Shiinaha

S: Ma heli karaa amar tijaabo ah oo kaliya dhowr tan?

J: Dabcan. Waxaan kuu soo rari karnaa xamuulka iyadoo la adeegsanayo adeegga LCL. (Cuntada weelka oo yar)

S: Haddii muunad bilaash ah?

J: Muunad la'aan, laakiin iibsaduhu wuxuu bixiyaa kharashka rarista.

S: Ma tahay alaab-qeybiye dahab ah oo ma hubisaa ganacsiga?

A: Waxaan 13 sano ku jirnaa alaab-qeybiye dahab ah waxaanan aqbalnaa dammaanadda ganacsiga.