Xiro u adkaystaSteelPdaahsan

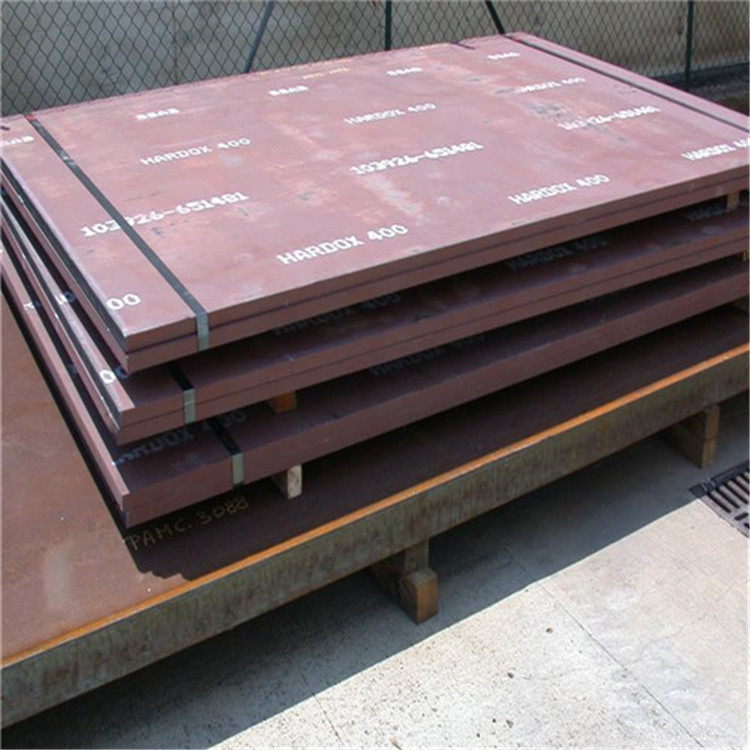

Saxan bir ah oo labajibbaaran oo xidhan xidhashada u adkaysata waa alaab saxan ah oo si gaar ah loogu isticmaalo xaaladaha xidhashada aagga weyn.Waxay ka samaysan tahay bir kaarboon yar oo caadi ah ama bir daawaha hoose leh oo adag iyo caag wanaagsan.Badeeco saxan ah oo ka samaysan lakab xidhid u adkaysta oo leh xoqid aad u fiican.

Saxanka birta u adkaysta ee bimetal waxa uu ka kooban yahay saxan bir kaarboon ah oo hooseeya iyo lakabka dahaadhka u adkaysta.Lakabka u adkaysta xirashada guud ahaan wuxuu xisaabiyaa 1/3-1/2 ee wadarta dhumucda.Marka la shaqeynayo, matrixku wuxuu bixiyaa sifooyin dhammaystiran sida xoogga, adkaanta iyo caagagga ka dhanka ah xoogagga dibadda, iyo lakabka u adkaysta wuxuu bixiyaa sifooyin u adkaysta xirashada oo buuxiya shuruudaha shuruudaha shaqada ee cayiman.

Lakabka u adkaysta wuxuu inta badan ka kooban yahay chromium alloy, iyo qaybaha kale ee daawaha sida manganese, molybdenum, niobium, iyo nikkel ayaa lagu daray isku mar.Carbides ee qaab-dhismeedka biraha ah waxaa loo qaybiyaa qaabka fiber-ka, iyo jihada fiberku waa mid siman dusha sare.Microhardness-ka carbide wuxuu gaari karaa ka sarreeya HV1700-2000, iyo engegnaanta dusha sare waxay gaari kartaa HRc58-62.Carbides Alloy waxay leeyihiin xasillooni xoog leh oo heerkul sare ah, ilaali adkaanta sare, sidoo kale waxay leeyihiin iska caabin oksaydh oo wanaagsan, waxaana si caadi ah loo isticmaali karaa gudaha 500°C.

Saxanka birta ah ee u adkaysta waxa uu leeyahay iska caabin heersare ah iyo wax qabad wanaagsan, waana la gooyn karaa, foorarsan karaa, alxanka iwm. habka dayactirka goobta , ku habboonaanta iyo sifooyinka kale, oo si ballaaran loo isticmaalo biraha, dhuxusha, sibidhka, korontada, dhalooyinka, macdanta, qalabka dhismaha, leben iyo tiles iyo warshadaha kale, marka la barbar dhigo alaabta kale, ayaa leh waxqabadka qiimaha sare leh, ayaa waxaa door biday in badan oo ka mid ah warshadaha iyo soo saarayaasha .

UsuaalFormad

| Qalab | Dhumucda | Ballaca | Dhererka |

| NM360 | 8 | 2200 | 8000 |

| NM360 | 10 | 2200 | 8000 |

| NM360 | 15 | 2200 | 8000 |

| NM400 | 12 | 2200 | 8000 |

| NM500 | 16 | 2200 | 8000 |

| NM360 | 20 | 2200 | 10300 |

| NM450 | 25 | 2200 | 12050 |

| NM400 | 30 | 2200 | 8000 |

| NM360 | 35 | 2090 | 10160 |

| NM400 | 40 | 2200 | 8000 |

| NM400 | 45 | 2200 | 8000 |

| NM400 | 50 | 2200 | 8000 |

| NM360 | 60 | 2200 | 7000 |

| NM360 | 135 | 0635 | 2645 |

| NM400 | 70 | 2200 | 9500 |

| NM400 | 80 | 2200 | 8000 |

Acodsi

1) Warshad tamarta kulaylka ah: Dhererka dhuxusha dhexdhexaadka ah ee dhuxusha, daboolka marawaxadaha, boodhka tuubada godka, tuubada dambaska, mishiinka mashiinka baaldiyada, tuubada isku xidha, tuubada burburiyaha dhuxusha, dhuxusha dhuxusha iyo xadhkaha mishiinka, gubida gubanaya, dhuxusha hopper iyo funnel liner, foornada kaalmaynta kulayliyaha hawada, weelka hagaha kala soocida.Qaybaha kor ku xusani ma laha shuruudo aad u sarreeya oo ku saabsan adkaanta iyo xidhashada caabbinta saxanka birta ah ee u adkaysta, iyo saxanka u adkaysta ee leh dhumucdiisuna tahay 6-10mm ee NM360/400 waa la isticmaali karaa.

2) Barxadda dhuxusha: dahaarka quudinta iyo dahaarka funnel, buushka hopper, daabka marawaxada, saxan hoose riixe, boodhka ururiyaha duufaanka, liner hagaha kookaha, dahaarka kubbadda dahaarka, digsi qaboojiyaha, gambaleel quudiyaha iyo kursiga salka, baaldi cajiin, giraan quudiyaha , dabaqa baabuurta iska roga.Deegaanka ay ku shaqeyso ee dayrka dhuxusha waa mid adag, waxaana jira shuruudo gaar ah oo loogu talagalay iska caabinta daxalka iyo xirashada caabbinta saxan birta u adkeysaneysa.Waxaa lagu talinayaa in la isticmaalo saxan bir ah oo xiran oo leh walxo NM400/450 HARDOX400 ah iyo dhumucdiisuna tahay 8-26mm.

3) Warshad sibidhka: dahaarka dahaarka, baadiyaha dhamaadka, boodhka ururiyaha duufaanka, garbaha kala soocida iyo garbaha hagaha, marawaxada iyo dahaarka, dahaarka baaldi soo kabashada, maroojis weel saxan hoose, qaybaha dhuumaha, frit saxan qaboojinta Dahaarka.Qaybahani waxay sidoo kale u baahan yihiin taargooyin bir ah oo xirxiran oo leh caabbinta xirashada iyo iska caabinta daxalka.Xiro taargo bir ah oo adkaysi u leh oo leh walxo NM360/400 HARDOX400 ah iyo dhumucdiisu tahay 8-30mmd waa la isticmaali karaa.

4) Mashiinada raritaanka: dejinta saxan saxan shiidan, saxan dahaarka hopper, saxan dahaarka qabsada, saxan caarada iska rogida tooska ah, jirka xamuulka qaada.Tani waxay u baahan tahay saxan bir ah oo u adkaysata xidhashada oo leh adkaysi aad u sarreeya iyo adkaysi.Waxa lagu talinayaa in la isticmaalo saxan bir ah oo xidhan oo leh walxo NM500 HARDOX450/500 ah iyo dhumucdiisu tahay 25-45MM.

5) Mashiinada macdanta: maaddada macdanta, jejebiyaha dhagaxa dhagaxa, daab, xadhkaha qaada, baffle.Qaybaha noocan oo kale ah waxay u baahan yihiin iska caabin aad u sarreeya, iyo walxaha la heli karo waa NM450/500 HARDOX450/500 saxan bir ah oo adkaysi u leh oo dhumucdiisu tahay 10-30mm.

6) Mashiinada dhismaha: saxanka iligga riixaya sibidhka, dhismaha isku-dhafka la taaban karo, xadhkaha isku dhafka ah, xadhkaha boodhka ururiyaha, saxanka caaryada mashiinka lebenka.Waxaa lagu talinayaa in la isticmaalo NM360/400 saxan bir xiran u adkaysta oo dhumucdiisu tahay 10-30mm.

7) Mashiinada dhismaha: xamuulka, cagaf-cagaf, saxan baaldi qodista, saxan dhinaca gees ah, saxanka hoose ee baaldi, daab, tuubada daloolida riiga rotary.Mashiinada noocaan ah waxay u baahan yihiin taarikada birta ah ee u adkaysata xidhashada kuwaas oo si gaar ah u xoog badan oo aad u adkaysta.Qalabka la heli karo waa NM500 HARDOX500/550/600 taarikada birta u adkaysta ee xoogga badan oo dhumucdeedu tahay 20-60mm.

8) Mashiinnada birta ah: Mashiinnada birta ee birta, suxulka gudbinta, saxanka dahaarka ee mashiinka birta birta, saxanka dahaarka ee mashiinka xoqida.Sababtoo ah mashiinada noocaan ah waxay u baahan yihiin heerkul sare oo adkaysi u leh, taarikada birta ah ee aad u adkeysata.Sidaa darteed, waxaa lagu talinayaa in la isticmaalo HARDOX600HARDOXHiTuf taxane ah oo xirashada taarikada birta ah.

9) Taarikada birta ah ee u adkeysaneysa xirashada waxaa sidoo kale loo isticmaali karaa dhululubada ciid-shiidka, daabadaha, deyrarrada xamuulka ee kala duwan, qeybaha mashiinnada wharf, qaybaha qaab dhismeedka, qaybaha dhismaha taayirrada tareenka, duub, iwm.

Waqtiga boostada: Jul-04-2023